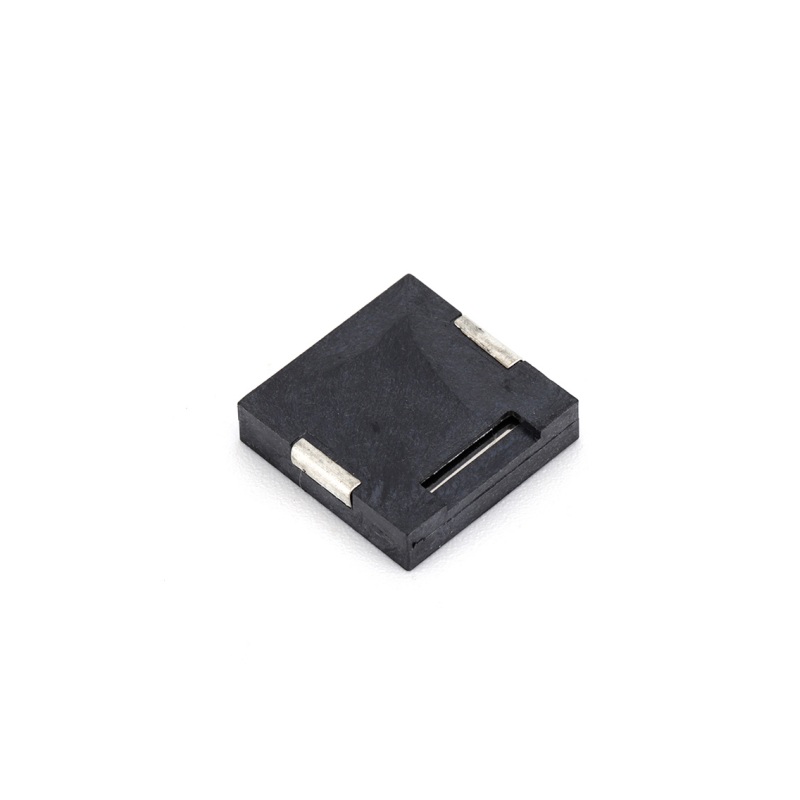

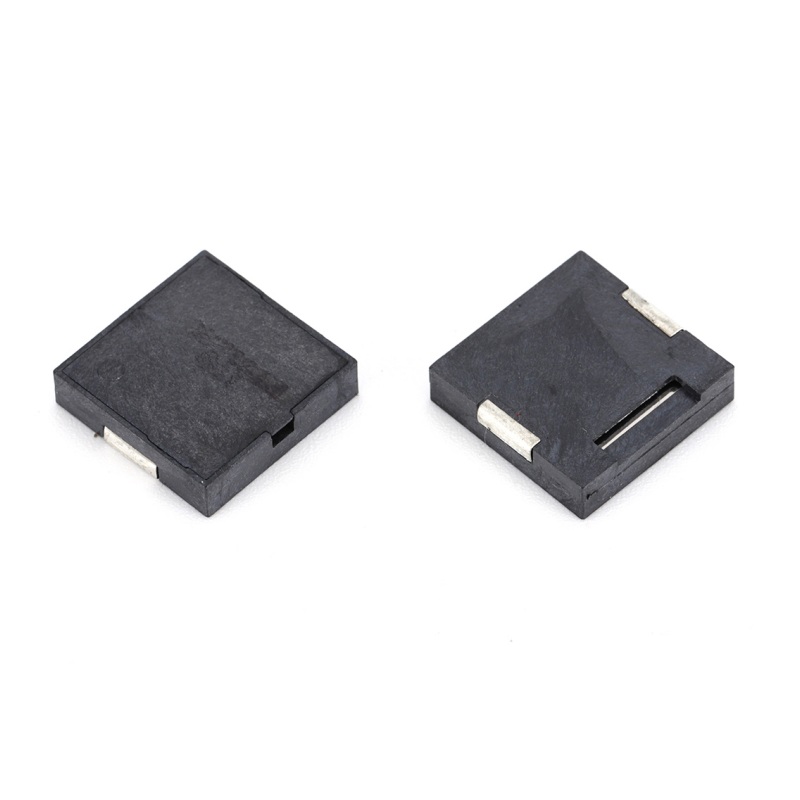

Hydz 12mm Isikwere Smd Uhlobo HYG1203A

Iimpawu zoMbane

| Into | HYG1203A |

| I-Voltage yokusebenza | Max20Vp-p

|

| Usetyenziso lwangoku | Ubukhulu be-8mA kwi-12Vp-p/Square Wave/4KHz

|

| Inqanaba loxinzelelo lwesandi | Min 80dB kwi-10cm/ 12Vp-p/Square Wave/4KHz

|

| Umthamo we-Electrostatic | 16000±30%pF kwi-1KHz/1V

|

| Ubushushu bokusebenza (℃) | -20~ +70

|

| Ubushushu boGcino (℃) | -30 ~ +80

|

| Izinto Zezindlu | I-LCP (Mnyama) |

| Ubungakanani | L12.0×W12.0×H3.0mm

|

PS: Vp-p=1/2duty, amaza asisikwere

Imilinganiselo kunye neMathiriyeli

Iyunithi: mm Ukunyamezela: ± 0.3mm

Ukuthatha ithuba letekhnoloji ye-acoustic ebanzi kunye noyilo lomatshini kunye neeseramikhi zokusebenza okuphezulu, izandi ze-SMD piezoelectric zihambelana noyilo oluncinci, olunoxinaniso oluphezulu lwezixhobo zombane.

Iimbonakalo

1. 12*12*3mm isikwere uhlobo smd

2. Incinci, incinci kwaye ilula

3. Inqanaba eliphezulu loxinzelelo lwesandi kunye nesandi esicacileyo

4. I-Reflowable

5. Ukunikezelwa kweTape & Reel

Usetyenziso

1. Izixhobo zeofisi ezahlukeneyo ezifana neePPCs iiprinta kunye neekeyboards

2. Izixhobo zasekhaya ezifana ne-oven microwave, ii-rice cookers njl.njl.

3. Ukuqinisekiswa kwesandi sezixhobo ezahlukeneyo zomsindo

Isaziso (Isoldering kunye nokunyuka)

1. Ukunyuka

Xa ufaka i-pin yetheminali yohlobo lwemveliso kwibhodi yesekethe eprintiweyo, nceda ufake i-terminal ye-pin ecaleni komngxuma webhodi.Ukuba imveliso icinezelwe ukuze i-terminal ingabikho emngxunyeni, i-pin terminal iya kutyhalelwa ngaphakathi kwimveliso kwaye izandi zinokungazinzi.

2. Ibhodi yomngxuma omacala amabini

Nceda uthintele ukusebenzisa ibhodi ecanda kabini emacaleni.Ukuba i-solder enyibilikisiweyo ichukumise isiseko se-pin terminal, inxalenye yeplastiki iya kunyibilika kwaye izandi zinokungazinzi.

3. Iimeko zeSoldering

(1) Iimeko zokuthambisa eziqukuqelayo zohlobo lwe-pin terminal

· Ubushushu: ngaphakathi kwe260°C±5°C

· Ixesha: phakathi kwe-10±1 sec.

• Indawo yokusoda ziitheminali ezikhokelayo ngaphandle kwe-1.5mm kumzimba wemveliso.

(2) Nceda ungagcini iimveliso ngokuthe ngqo emgangathweni ngaphandle kwanto phantsi kwazo ukuze uphephe iindawo ezifumileyo kunye/okanye ezinothuli.

(3) Nceda ungayigcini imveliso kwiindawo ezinjengendawo eshushu efumileyo okanye nayiphi na indawo echatshazelwe lilanga okanye ukungcangcazela okugqithisileyo.

(4) Nceda usebenzise iimveliso ngokukhawuleza emva kokuba iphakheji ivuliwe, kuba iimpawu zingancitshiswa kumgangatho, kunye / okanye zithotywe kwi-solderability ngenxa yokugcinwa phantsi kweemeko ezimbi.

(5) Nceda uqhagamshelane nommeli wethu wokuthengisa okanye injineli nanini na xa iimveliso ziza kusetyenziswa kwiimeko ezingadweliswanga ngasentla.

4. Imeko-bume yokuSebenza

Le mveliso yenzelwe isicelo kwindawo eqhelekileyo (ubushushu begumbi eliqhelekileyo, ukufuma kunye noxinzelelo lwe-atmospheric).

Musa ukusebenzisa iimveliso kwindawo yekhemikhali efana negesi yeklorine, iasidi okanye igesi yesulfide.

Iimpawu zisenokwehlelwa yikhemikhali kunye nemathiriyeli esetyenziswa kwiimveliso.

(2) Imeko ye-soldering nge-soldering iron yohlobo lwe-pin terminal

· Ubushushu: ngaphakathi kwe-350±5°C

· Ixesha: ngaphakathi kwe-3.0±0.5 sec.

• Indawo yokusoda ziitheminali ezikhokelayo ngaphandle kwe-1.5mm kumzimba wemveliso

3

· Iprofayile yobushushu: Isazobe 1

· Inani lamaxesha: Ngaphakathi kwe-2 ubuninzi

4. Ukuhlamba

Nceda ugweme ukuhlamba, ekubeni le mveliso ayisosakhiwo esitywiniweyo.

5. Emva kokuNyusa iMveliso

(1) Ukuba imveliso idada kwibhodi yesekethe eprintiweyo, nceda ungayityhala.Xa ucinezela, i-terminal ye-pin ityhalelwa ngaphakathi kwimveliso kwaye izandi zinokungazinzi.

(2) Nceda ungasebenzisi amandla (umothuko) kwimveliso.Ukuba kunyanzeliswa, ityala lisenokuphuma.

(3) Ukuba ityala liyaphuma, nceda ungaphinde udibanise.Nokuba kubonakala ngathi ibuyele kweyakuqala, izandi zinokungazinzi.

(4) Nceda ungavutheli umoya kwimveliso ngokuthe ngqo.Umoya ovuthuzayo usebenzisa amandla kwidiaphragm yepiezoelectric ngomngxuma wokukhupha isandi;iintanda zinokuvela emva koko izandi zingazinzi.Ukongeza, kukho ithuba lokuba ityala lingaphuma.

Isaziso(Ukuphatha)

1. I-ceramic ye-piezoelectric isetyenziswe kule mveliso.Nceda usebenzise inkathalo ekuphatheni, kuba i-ceramic yaphukile xa kusetyenziswe amandla agqithisileyo.

2. Nceda ungasebenzisi amandla kwidiaphragm ye-piezoelectric ukusuka kumngxuma wokukhupha isandi.Ukuba kunyanzeliswa, kubakho iintanda kwaye nezandi zinokungazinzi.

3. Nceda ungayishiyi imveliso okanye usebenzise ukothuka okanye utshintsho lobushushu kuyo.Ukuba kunjalo, i-LSI inokutshatyalaliswa yintlawulo (i-surge voltage) eyenziwe.

ibonisa umzekelo wokuqhuba isekethe usebenzisa i-zener diode.

Isaziso (Ukuqhuba)

1. Ukufuduka kwe-ag kunokwenzeka ukuba amandla ombane e-DC asetyenziswa kwimveliso phantsi kokusingqongileyo kokufuma okuphezulu.Nceda uphephe ukuyisebenzisa phantsi kokufuma okuphezulu kwaye uyilo isekethe ukuze ungasebenzisi amandla ombane we-DC.

2. Xa uqhuba umkhiqizo nge-IC, nceda ufake ukuchasana kwe-1 ukuya kwi-2kΩ kwichungechunge.Injongo kukukhusela i-IC kunye nokufumana isandi esizinzileyo.(Nceda ubone umzobo 2a).Ukufaka i-diode ngokuhambelana nemveliso kunempembelelo efanayo.(Nceda ujonge isazobe 3b)

3. I-Flux okanye i-Coating Agent, njl., Ii-Solvents ezahlukeneyo Kunokwenzeka ukuba i-solvent ye-liquid ingene ngaphakathi kwimveliso, ekubeni le mveliso ayikho isakhiwo esitywiniweyo.Ukuba ulwelo lungene ngaphakathi kwaye lufakwe kwi-diaphragm ye-piezoelectric, ukungcangcazela kwayo kunokuthintelwa.Ukuba uncamathela kwisiphambuka sombane, uqhagamshelo lombane lunokusilela.

Ukuthintela ukungazinzi kwesandi, nceda ungavumeli ulwelo ukuba lungene ngaphakathi kwimveliso.